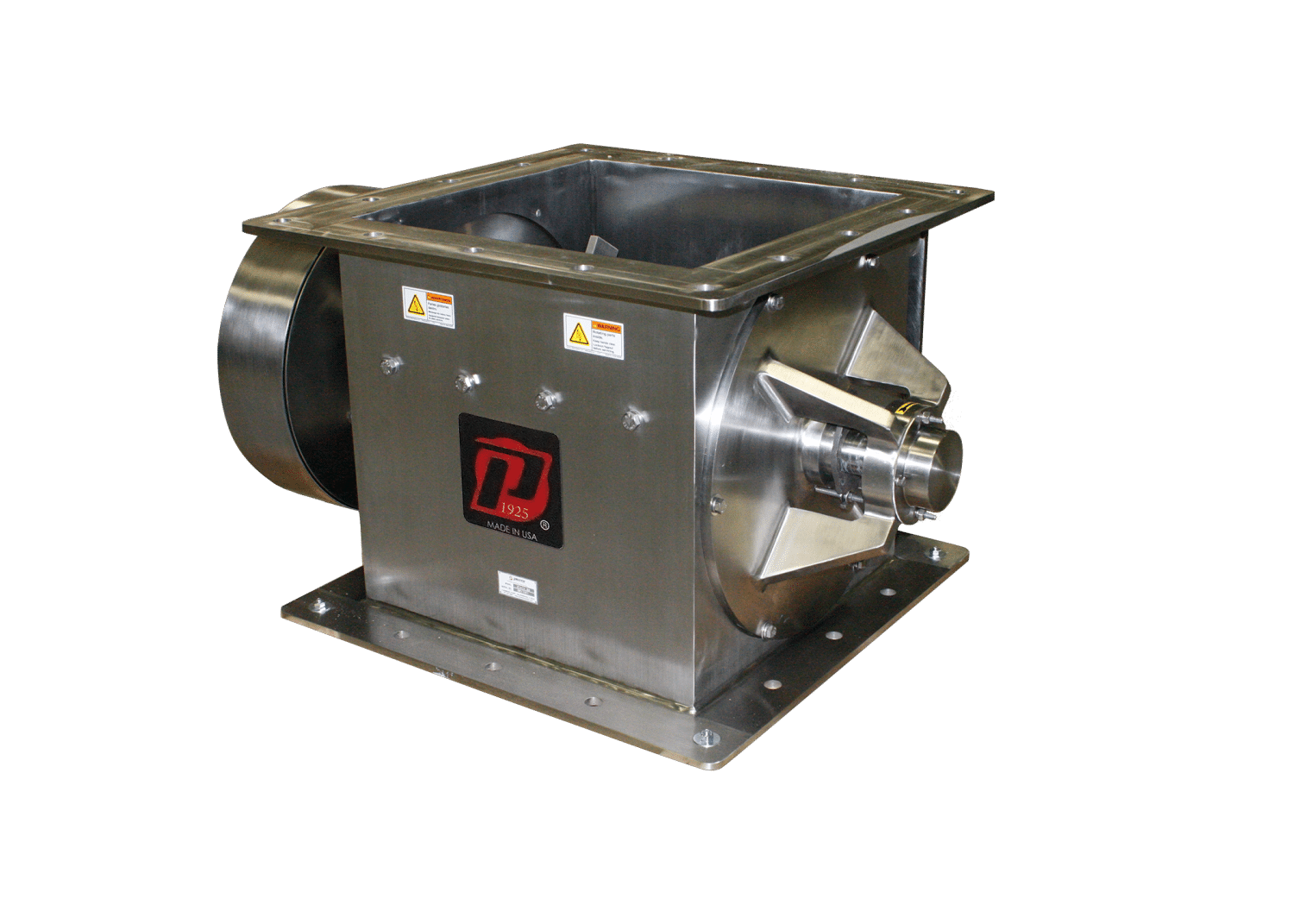

Prater Einwellen-Klumpenbrecher (auch Flockenbrecher oder umgekehrt genannt) sind ein einfaches, dauerhaftes und wirtschaftliches Mittel zur Aufbereitung von Materialien, die durch Lagerung, Transport oder Vermischung verdichtet oder verklumpt sind. Die gleichzeitige Anwendung von sanftem Schlag und Scherung führt zu frei fließenden Materialien mit gleichmäßiger Größenverteilung. Viele Industriezweige verlangen eine gleichmäßige Größenverteilung beim Mischen, Fördern und Verpacken ihrer Endprodukte. Prater-Klumpenbrecher bieten Kosteneinsparungen, rationalisierte Betriebseffizienz und verbesserte Produktqualität.

Prater Doppelwellen-Flockenbrecher bieten die gleichen Vorteile wie Prater Einzelwellen-Klumpenbrecher, jedoch mit einem niedrigeren Profil. Ausgestattet mit gegenläufigen Klingen sind diese Flockenbrecher ideal für die Konditionierung oder Granulierung von Materialien, die in Verdichtungsanlagen, Recycling- oder Entsorgungsanlagen verdichtet werden.

Diese Präzisionswerkzeuge sind bei einer Vielzahl von Produkten hilfreich, z. B:

- Zucker

- Salz

- Harze

- Pigmente

- Nudeln

- Nutrazeutika

- Mineralien

- Ofenstaub

- Hanf

- Filterkuchen

- Düngemittel

- Chemikalien

- Getreide

- Keramische Pulver