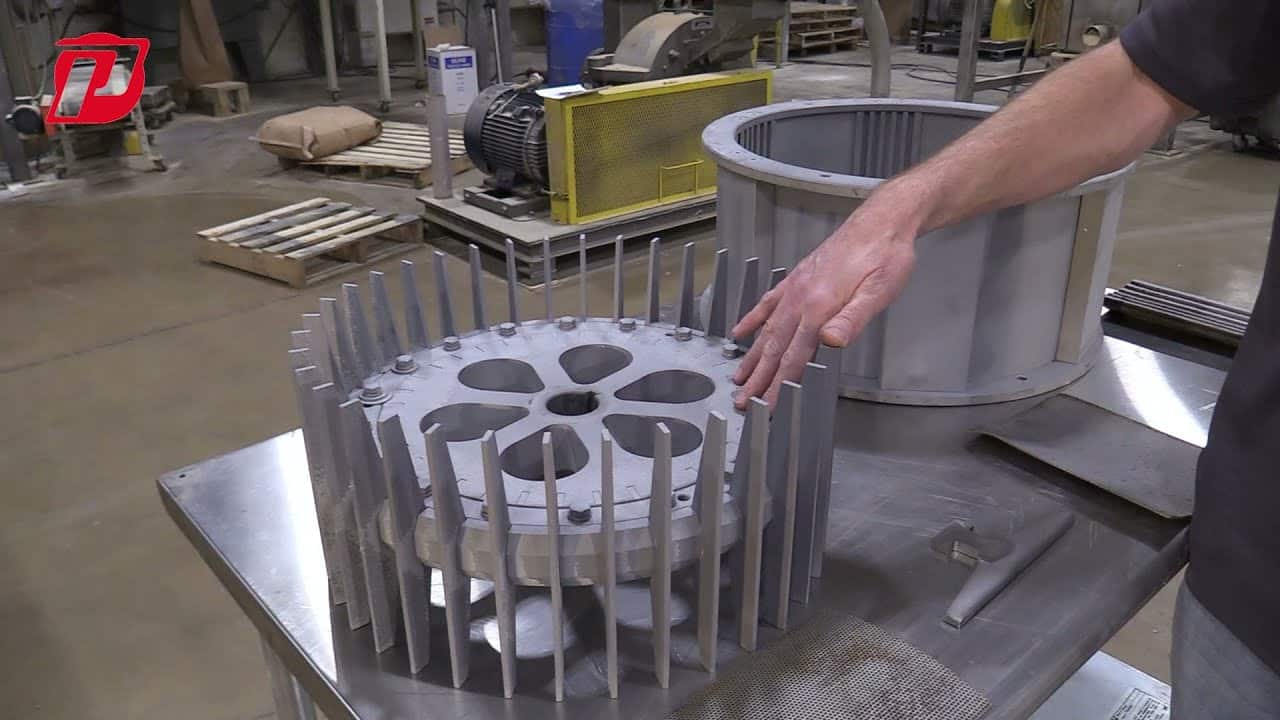

Rotary Airlock Valve Feeders manufactured by Prater are designed to provide improved performance to bulk material processing and production operations. In dry material metering applications, our valves ensure accurate material loading and unloading while also functioning as highly efficient rotary airlocks; minimizing pressure loss throughout the system.

Our customers rely on Prater Rotary Valve Feeders to perform various functions such as:

- Feed process materials into pneumatic conveying applications

- Regulate the flow of material from one chamber to another

- Metering of process materials in loading and unloading applications

- Minimize air loss while transferring material between vessels with different pressures

Prater’s Rotary Airlock Valves can be configured and customized for most application requirements, especially for materials that may be highly abrasive. We understand the need for feeding more material at lower speeds, which is why our rotary airlock feeders are manufactured with larger pockets. In turn, this design minimizes air leakage, provides the benefit of longer life, and ensures a higher return on investment.

Wherever dry free-flowing powders, granules, crystals, or pellets are used, our rotary valves perform well in a wide range of industry applications. Common materials include cement, ore, sugar, pigments, wood chips, minerals, grains, plastics, coal, soy white flakes, fly ash, flour, gypsum, lime, coffee, carbon black, and pharmaceuticals.